4H-SiC Boules Advantages 4-8" N-Type Conductive SiC Crystals

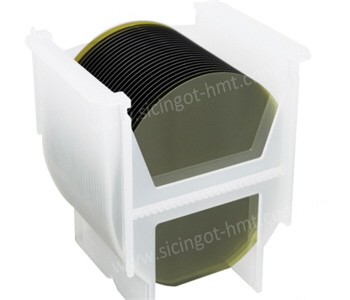

Silicon carbide (SiC) is composed of carbon and silicon elements, and is equivalent to gallium nitride (GaN) as a third-generation compound semiconductor material. Natural SiC is very rare and is mostly artificial. SiC has more than 200 crystal forms, and the main crystal form is 4H-SiC, which is the first choice for SiC devices.HMT company foucs on 4H-Conductive N type SiC Boules manufacturing both for 4 inch,6 inch and 8 inch. The thickness of SiC Boule about 20mm.

As the third generation semiconductor, SiC has excellent material properties. Compared with the first generation of single element semiconductor materials represented by silicon and the second generation of compound semiconductor materials represented by GaN,SiC has superior material characteristics such as wide band gap, high thermal conductivity and high breakdown electric field strength, so that semiconductor devices made of silicon carbide can meet the application requirements under high temperature, high pressure, high frequency and other conditions.

The advantages of SiC devices and Si devices are as follows:

(1) High temperature resistance: the band gap width and thermal conductivity of SiC are about 3 times that of silicon, theoretically SiC devices can work at an environment of over 600 ° C, and the limit working environment of silicon devices is limited to 175 ° C.

(2) High pressure resistance: the breakdown electric field strength of SiC is about 10 times that of silicon, which greatly improves the voltage resistance characteristics of the device.

(3) Low loss: SiC has about 2 times the saturated electron drift rate of silicon and very low on-resistance, which can reduce energy loss, such as the total energy loss of silicon-based MOSFET of the same specification can be reduced by 70% compared with silicon-based IGBT, improving conversion efficiency. The demand for high-voltage platforms in new energy vehicles, photovoltaic and other application scenarios is gradually increasing, and the use of SiC instead of silicon to prepare semiconductor devices can achieve higher work efficiency with less power consumption in high temperature and high pressure environments.

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SiC : Industrial Ceramic vs Semiconductor Applications

- Introduction to the main functions of PbootCMS

How Does AI Help Singe Crystal SiC Boule Growth

- Introduction to the main functions of PbootCMS

Technical Analysis of SiC Wafer For Power Semiconductor Devices in New Energy Vehicles

- Introduction to the main functions of PbootCMS

SiC industry is stepping into 8 inch with 12 inch substrates making accelerated breakthroughs

CONTACT US

Contact: Mr.Kimrui

Phone: 15366208370

Tel: 15366208370

Email: kim@homray-material.com

Add: LiSheng Industrial Building, 60SuLi Road, WuZhong District, JiangSu Province, P.R.China.