100mm 4 inch SiC Wafer Manufacturer 4H-N Type

As an important raw material for the third-generation semiconductors, HMT Semiconductors specializes in manufacturing precision-engineered 4-inch (100...

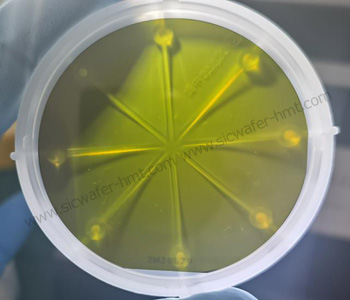

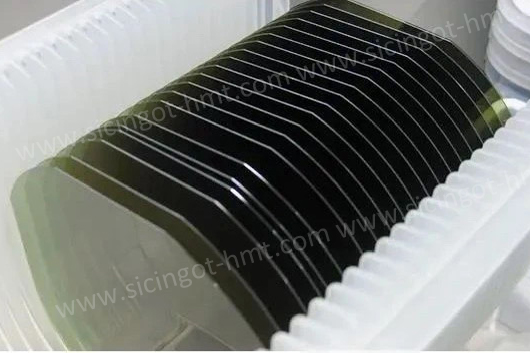

As an important raw material for the third-generation semiconductors, HMT Semiconductors specializes in manufacturing precision-engineered 4-inch (100mm) 4H-N type silicon carbide wafers with multiple performance grades. Conductive SiC substrate is a monocrystalline formed by conductive SiC crystal processing through cutting, grinding, polishing, cleaning and other processes. We have P grade 4 inch SiC wafers which used for SiC diodes, SiC MOSFET and other power devices after homogeneous epitaxial growth.

The P-grade 4H-N SiC wafers feature:

Optimized resistivity (0.015-0.028 Ω·cm) for efficient current flow

Microroughness <0.2 nm Ra after CMP processing

Low defect density (<0.5 cm²) for reliable homoepitaxial growth

Customizable off-axis orientations (4° ±0.5° towards <11-20>)

SiC Electrical Characteristics:

SiC Electrical Characteristics:

1. High voltage resistance: the breakdown electric field strength is large, 10 times that of silicon, and the device prepared with silicon carbide can greatly improve the voltage capacity, operating frequency and current density, and greatly reduce the on-off loss of the device.

2. High temperature resistance: semiconductor devices at higher temperatures, will produce carrier intrinsic excitation phenomenon, resulting in device failure. The larger the band-gap width, the higher the limit operating temperature of the device. The band gap of silicon carbide is nearly 3 times that of silicon, which can ensure the reliability of silicon carbide devices under high temperature conditions. The limit operating temperature of silicon devices generally cannot exceed 300 ° C, and the limit operating temperature of silicon carbide devices can reach more than 600 ° C.

3. Achieve high frequency performance: The saturated electron drift rate of silicon carbide is large, which is twice that of silicon, which determines that silicon carbide devices can achieve higher operating frequency and higher power density.

Downstream Products and Applications

SiC Wafers materials are suitable for high temperature, high voltage, high current and other working environments, and are widely used in new energy vehicles, charging piles, photovoltaic wind power, energy storage, rail transit, smart grid, industrial power supply, industrial drive, white goods and other fields.

SiC power devices with high voltage, high current, high temperature, high frequency, low loss and other unique advantages will greatly improve the energy conversion efficiency of the existing use of silicon-based power devices, and have a significant and far-reaching impact on the field of efficient energy conversion, the main application areas are electric vehicles/charging piles, photovoltaic new energy, rail transit smart grid and so on.

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SiC : Industrial Ceramic vs Semiconductor Applications

- Introduction to the main functions of PbootCMS

How Does AI Help Singe Crystal SiC Boule Growth

- Introduction to the main functions of PbootCMS

Technical Analysis of SiC Wafer For Power Semiconductor Devices in New Energy Vehicles

- Introduction to the main functions of PbootCMS

SiC industry is stepping into 8 inch with 12 inch substrates making accelerated breakthroughs

CONTACT US

Contact: Mr.Kimrui

Phone: 15366208370

Tel: 15366208370

Email: kim@homray-material.com

Add: LiSheng Industrial Building, 60SuLi Road, WuZhong District, JiangSu Province, P.R.China.