SiC Boule Manufacturer For Laser Cutting Testing

HMT supplies 2-8" conductive SiC boules (10-30mm thick) for laser cutting & diamond wheel testing. Custom geometries. Top 10 SiC manufacturer. Get quo...

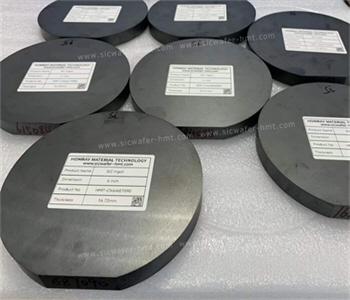

Top 10 SiC Wafer Manufacturer-HMT specializing in Test grade Conductive SiC Boules for R&D and equipment calibration. Our products including 2 inch 4 inch 6 inch and 8 inch For Laser Cutting testing、diamond grinding wheel testing etc. Our Conductive testing SiC boule thickness about 10-20mm and we support customization for all dimension SiC Crystal Boules. We always providing bottom price to worldwide customers. Custom Geometry & Resistivity Boules available. Request your cost-optimized testing solution today.

SiC crystals have the following advantages:

(1) Mechanical properties: SiC crystal has extremely high hardness and good wear resistance, which is the only crystal second to diamond in the materials that have been found. Due to the excellent properties of SiC mechanics, powder SiC is often used in cutting or polishing industry, and the wear-resistant coating on some workpieces will also use SiC coating, and the wear-resistant coating on the deck of Shandong ship is composed of SiC.

(2) Thermal properties: the thermal conductivity of SiC is 3 times that of traditional semiconductor Si and 8 times that of GaAs. The heat production of the device prepared by SiC can be quickly conducted away, so the requirements of the heat dissipation conditions of the SiC device are relatively loose, and it is more suitable for the preparation of high-power devices. SiC has stable thermodynamic properties. Under normal pressure conditions, SiC will be directly decomposed into Si and C vapor at higher temperatures, without melting.

(3) Chemical properties: SiC has stable chemical properties, good corrosion resistance, and does not react with any known acid at room temperature. SiC placed in the air for a long time will slowly form a thin layer of dense SiO2, preventing further oxidation reactions.

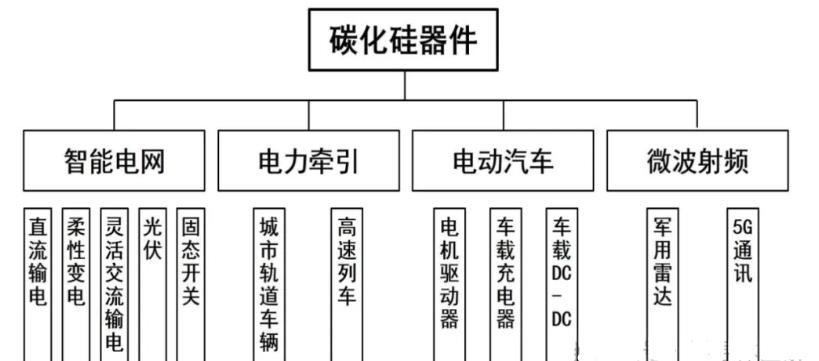

(4) Electrical properties: SiC as a representative material of wide bandgap semiconductors, 6H-SiC and 4H-SiC bandgap widths are 3.0 eV and 3.2 eV respectively, which is 3 times that of Si and 2 times that of GaAs. Semiconductor devices made of SiC have smaller leakage current and larger breakdown electric field, so SiC is considered as an ideal material for high-power devices. The saturated electron mobility of SiC is also 2 times higher than that of Si, and it also has obvious advantages in the preparation of high-frequency devices. P-type SiC crystals or N-type SiC crystals can be obtained by doping the impurity atoms in the crystals.

(5) Optical properties: Due to the relatively wide band gap, the undoped SiC crystal is colorless and transparent. The doped SiC crystals show different colors due to their different properties, for example, 6H-SiC is green after doping N; 4H-SiC is brown. 15R-SiC is yellow. Doped with Al, 4H-SiC appears blue. It is an intuitive method to distinguish SiC crystal type by observing the difference of color.

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SiC : Industrial Ceramic vs Semiconductor Applications

- Introduction to the main functions of PbootCMS

How Does AI Help Singe Crystal SiC Boule Growth

- Introduction to the main functions of PbootCMS

Technical Analysis of SiC Wafer For Power Semiconductor Devices in New Energy Vehicles

- Introduction to the main functions of PbootCMS

SiC industry is stepping into 8 inch with 12 inch substrates making accelerated breakthroughs

CONTACT US

Contact: Mr.Kimrui

Phone: 15366208370

Tel: 15366208370

Email: kim@homray-material.com

Add: LiSheng Industrial Building, 60SuLi Road, WuZhong District, JiangSu Province, P.R.China.